The heart of any high-performance cooking or industrial appliance lies in its ability to generate and distribute heat effectively. A key component driving this efficiency is the SUS304 electric heating pipe, a pinnacle of advanced heating technology that ensures reliability and precision. This guide will walk you through the essential aspects of these components, explaining how to identify quality, select the right specifications, and understand their role in the sophisticated devices they power. Understanding these elements is the first step to appreciating the seamless performance and superior results they deliver.

What Makes SUS304 the Ideal Material?

SUS304 is a specific grade of stainless steel renowned for its excellent corrosion resistance, strength, and durability, making it the premier choice for SUS304 heating elements. When used to create these components, the material offers significant advantages. It can withstand repeated exposure to high temperatures without degrading or oxidizing, which is crucial for longevity and safety in appliances operating at intense heat. Furthermore, its resistance to corrosion from moisture, steam, and cleaning agents ensures the element maintains its structural integrity and performance over countless cycles. This inherent toughness provides a consistent and reliable heat source for perfect results, and its non-reactive surface makes it a hygienic choice for kitchen and food processing equipment.

How to Select a High Temperature Heating Pipe

When your application demands consistent and intense heat, selecting the right component is critical. A high temperature heating pipe made from SUS304 is designed specifically for these demanding environments. To choose the correct one, you must evaluate several operational factors. First, consider the required wattage and voltage to ensure compatibility with your system's power supply. Next, analyze the wattage density—the power emitted per surface area—as this directly affects how quickly the element heats up and its surface temperature. The physical shape, length, and termination style are also vital for ensuring a proper fit and even heat distribution within an appliance. A well-chosen high temperature heating pipe is the secret behind rapid preheating, the elimination of frustrating hot spots, and perfectly controlled cooking processes.

Leveraging Customizable Electric Heating Solutions

Modern appliances often feature unique designs and specific performance goals, which means a one-size-fits-all approach to heating is rarely effective. This is where customizable electric heating solutions become invaluable. Expert manufacturers can engineer a SUS304 electric heating pipe into virtually any configuration—intricate coils, compact U-bends, or long straight rods—to fit perfectly within the designated space of an oven, fryer, or water heater. Customization can also include adding fins for improved air heating or specialized mounting brackets for easy installation. This tailored approach ensures that heat is delivered precisely where it is needed most, maximizing energy efficiency and overall functional performance. For any unique design, customization allows SUS304 heating elements to be fully optimized for the task.

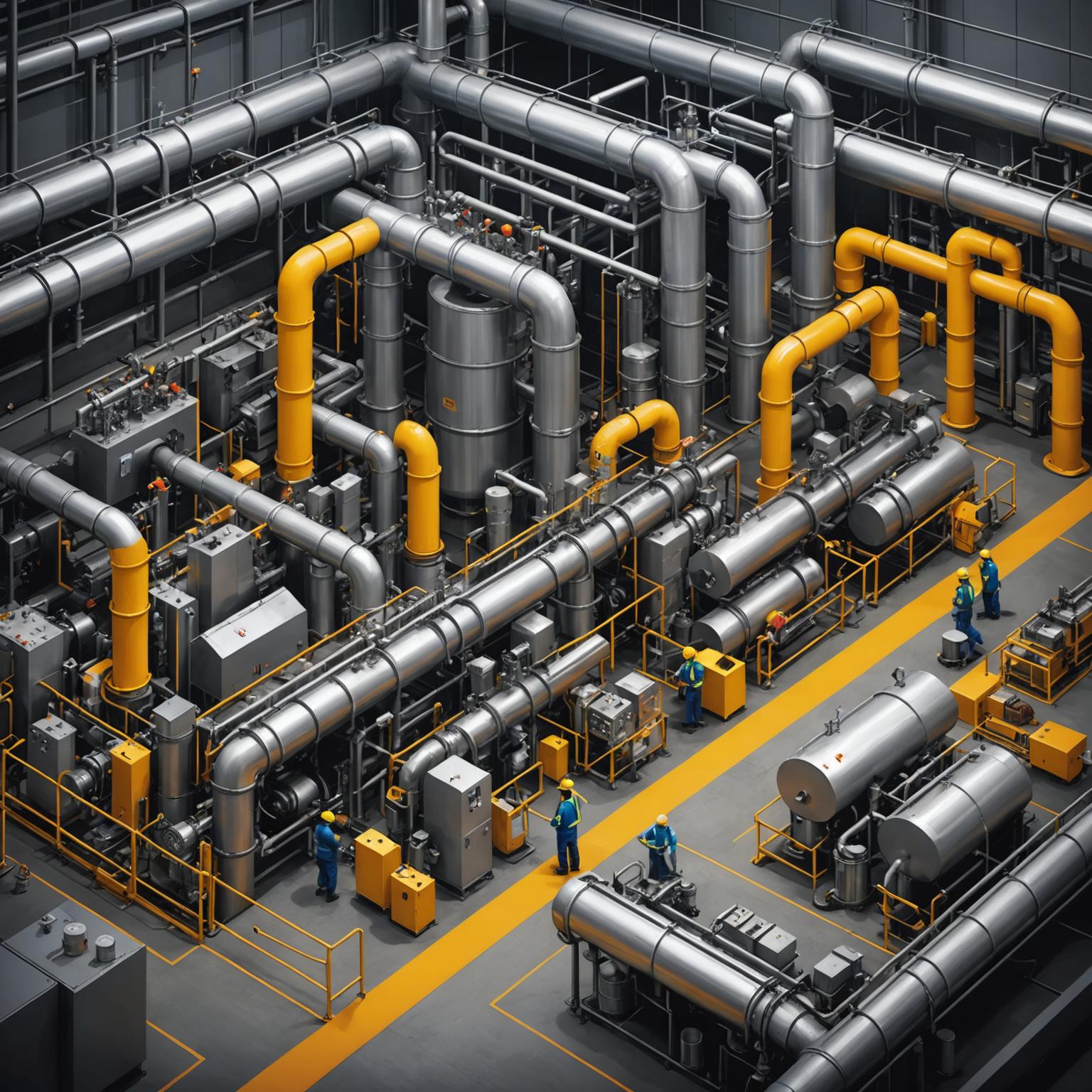

The Role of Advanced Heating Technology in Modern Appliances

Ultimately, the fusion of superior materials like SUS304 steel with thoughtful engineering culminates in the advanced heating technology we see in today's top-tier appliances. A robust and efficient heating element serves as the foundation, but it is part of a larger, intelligent system. When paired with smart controls, quality insulation, and innovative appliance design, it delivers an unparalleled user experience, just like in a modern oven with rapid, even heating. This synergy allows for precise temperature management, significantly faster pre-heating times, and exceptional cooking consistency. By following this guide to understand these core components, both consumers and designers can ensure they are leveraging the very best in thermal engineering for any culinary or industrial challenge.