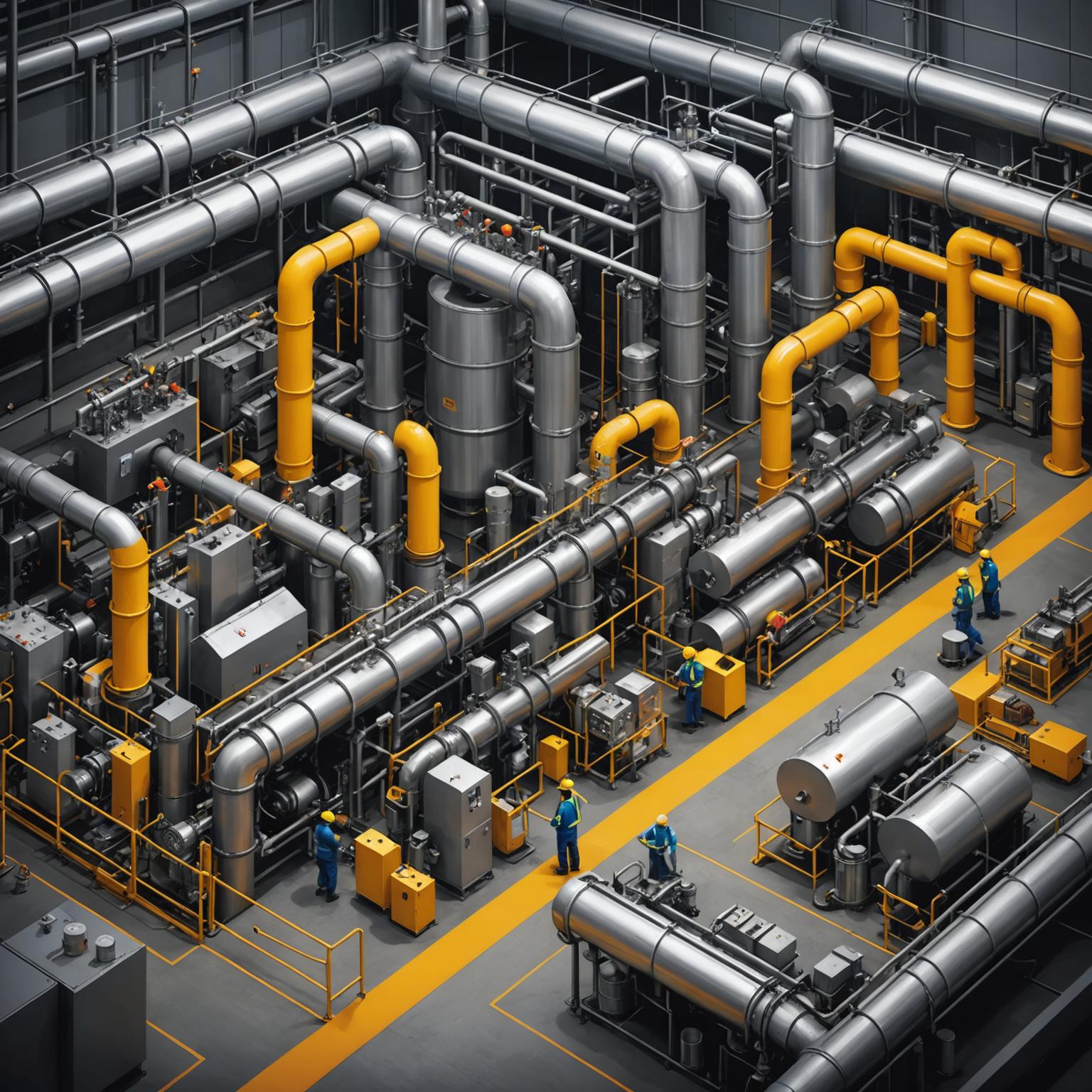

In modern industrial applications, the Heating pipe, particularly within induction heating systems, serves as a cornerstone of efficiency and precision. These components are not merely conduits but are sophisticated tools engineered to deliver controlled thermal energy without direct contact. By leveraging the principles of electromagnetic induction, these systems revolutionize processes such as brazing, soldering, stress relieving, and metal forming. The ability to generate intense, localized heat rapidly makes the induction heating pipe an indispensable part of advanced manufacturing, ensuring high-quality results while optimizing energy consumption and operational speed.

When selecting materials for industrial heating components, the choice often falls on steel heating pipes. Steel offers a robust combination of durability, thermal conductivity, and magnetic properties that are ideal for the rigors of induction heating. The material's ability to withstand extreme temperatures and repeated thermal cycling ensures a long service life and reliable performance. In systems like the NovaForge or HT-250801, the structural integrity of steel allows for the creation of intricately shaped coils that can conform to various workpieces, ensuring uniform heat distribution. This resilience is critical in heavy-duty environments where components are subjected to significant mechanical and thermal stress, making steel the material of choice for dependable and efficient heating operations.

Achieving optimal heating pipe heating efficiency is paramount for cost-effective and sustainable manufacturing. Efficiency in an induction system is determined by several factors, including the operating frequency, power input, and the geometric relationship between the heating coil and the workpiece. A well-designed system minimizes energy loss by precisely coupling the electromagnetic field to the target material. This creates eddy currents that generate heat exactly where it is needed, reducing waste heat and overall energy consumption. Advanced systems incorporate features like adjustable induction coils and smart power delivery to maintain high efficiency across various applications, ensuring that the maximum amount of electrical energy is converted into useful thermal energy for the process at hand.

To unlock the full potential of an induction heating system, a range of heating pipe accessories is required. These accessories are not just add-ons; they are integral to the system's safety, precision, and longevity. A crucial component is the power supply, which must be capable of delivering stable, high-frequency power. Cooling systems, often water-based chillers, are essential to prevent the induction coil itself from overheating, thereby protecting the investment and ensuring consistent operation. Furthermore, custom fixtures and jigs are used to securely hold the workpiece in the optimal position relative to the coil. Safety equipment, such as heat-resistant gloves and protective shields, is non-negotiable, safeguarding operators from the intense heat generated during the process.

Implementing an effective heating pipe sizing guide is critical for tailoring an induction system to a specific task. The term "sizing" in this context refers to the selection of the induction coil's diameter, shape, and number of turns. The correct size and geometry are dictated by the characteristics of the workpiece, including its material, size, and the specific area to be heated. For instance, heating a large, flat surface requires a different coil design than heating a small, intricate joint. A proper heating pipe sizing guide ensures that the magnetic field is concentrated effectively, leading to rapid, uniform heating and preventing issues like overheating or uneven treatment. Careful consideration of these parameters is the key to repeatable, high-quality results in any induction heating application.

Understanding Steel Heating Pipes in Induction Systems

When selecting materials for industrial heating components, the choice often falls on steel heating pipes. Steel offers a robust combination of durability, thermal conductivity, and magnetic properties that are ideal for the rigors of induction heating. The material's ability to withstand extreme temperatures and repeated thermal cycling ensures a long service life and reliable performance. In systems like the NovaForge or HT-250801, the structural integrity of steel allows for the creation of intricately shaped coils that can conform to various workpieces, ensuring uniform heat distribution. This resilience is critical in heavy-duty environments where components are subjected to significant mechanical and thermal stress, making steel the material of choice for dependable and efficient heating operations.

Maximizing Heating Pipe Heating Efficiency

Achieving optimal heating pipe heating efficiency is paramount for cost-effective and sustainable manufacturing. Efficiency in an induction system is determined by several factors, including the operating frequency, power input, and the geometric relationship between the heating coil and the workpiece. A well-designed system minimizes energy loss by precisely coupling the electromagnetic field to the target material. This creates eddy currents that generate heat exactly where it is needed, reducing waste heat and overall energy consumption. Advanced systems incorporate features like adjustable induction coils and smart power delivery to maintain high efficiency across various applications, ensuring that the maximum amount of electrical energy is converted into useful thermal energy for the process at hand.

Essential Heating Pipe Accessories for Optimal Performance

To unlock the full potential of an induction heating system, a range of heating pipe accessories is required. These accessories are not just add-ons; they are integral to the system's safety, precision, and longevity. A crucial component is the power supply, which must be capable of delivering stable, high-frequency power. Cooling systems, often water-based chillers, are essential to prevent the induction coil itself from overheating, thereby protecting the investment and ensuring consistent operation. Furthermore, custom fixtures and jigs are used to securely hold the workpiece in the optimal position relative to the coil. Safety equipment, such as heat-resistant gloves and protective shields, is non-negotiable, safeguarding operators from the intense heat generated during the process.

A Practical Heating Pipe Sizing Guide

Implementing an effective heating pipe sizing guide is critical for tailoring an induction system to a specific task. The term "sizing" in this context refers to the selection of the induction coil's diameter, shape, and number of turns. The correct size and geometry are dictated by the characteristics of the workpiece, including its material, size, and the specific area to be heated. For instance, heating a large, flat surface requires a different coil design than heating a small, intricate joint. A proper heating pipe sizing guide ensures that the magnetic field is concentrated effectively, leading to rapid, uniform heating and preventing issues like overheating or uneven treatment. Careful consideration of these parameters is the key to repeatable, high-quality results in any induction heating application.