What is ceramic glass?

Ceramic glass is one of the most innovative materials in modern engineering, combining the unique properties of ceramics and traditional glass to create products that are both durable and versatile. Due to its strength, high temperature and aesthetic appeal, it offers a wide range of applications. Unlike regular glass, ceramic glass does not break easily, making it a favorite in industries that require appearance and elasticity.

This advanced material has the characteristics of revolutionizing industries such as automotive, aerospace and household appliances. You often find it on the top of the stove, in the high temperature oven, and even the most advanced lab equipment. The durability and efficiency provided by ceramic glass distinguishes it from traditional materials.

Ceramic glass characteristics: the key to its versatility

The true genius of ceramic glass lies in its characteristics. It can withstand extreme temperatures without cracking or deformation, which is a case where high durability is required. Ceramic glass characteristics include high temperature resistance, low thermal conductivity and high-end visual clarity. This set of functions is particularly important in industries with extreme environmental conditions.

Another cornerstone of ceramic glass is its low thermal expansion rate. This feature reduces the possibility of damage even if the material undergoes rapid temperature changes. In contrast, conventional glass will break or break under similar conditions. High temperature ceramic glass products have entered the state-of-the-art technology used in laboratories, vehicle exhaust systems, and even circuits.

Where is shining in ceramic glass: cross-industry applications

The use of ceramic glass is indeed widespread. You will find this material in kitchens, labs, cars, and even spacecraft. For example, in the field of household appliances, ceramic glass is used extensively on top of stoves because it provides a stylish, modern design while distributing heat evenly. Similarly, laboratory equipment usually uses ceramic glass to resist heating.

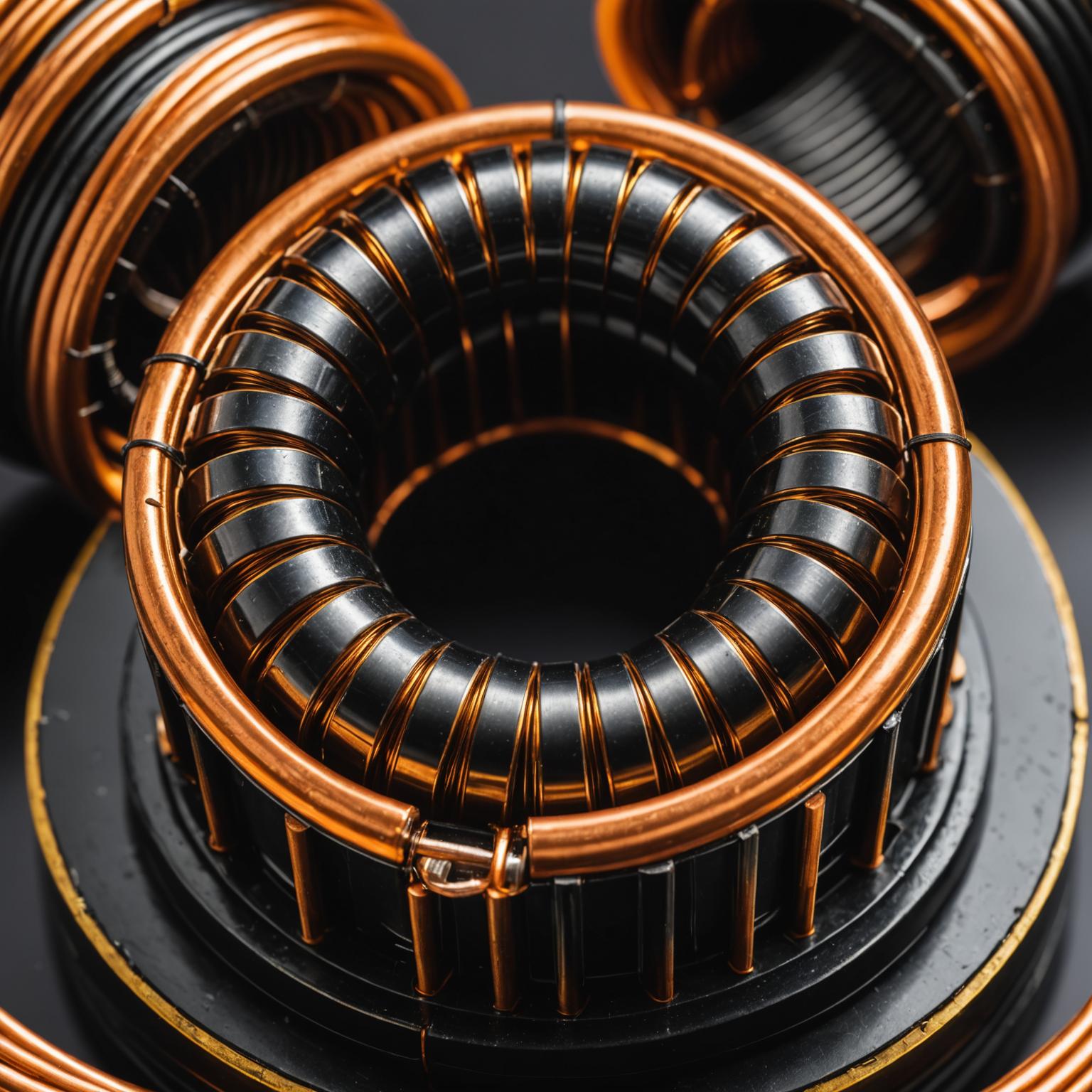

In the field of advanced technology, ceramic glass proves its importance in electrical components. Taking the ring inductor as an example, this is a miracle of modern coil engineering. Although not made entirely from ceramic glass, the high temperature resistance and non-conductivity of ceramic glass make it an essential support material in such components. By blocking electromagnetic interference and increasing efficiency, ceramic glass contributes to smoother performance and longer electrical equipment durability.

The Future of Ceramic Glass Manufacturing

The demand for ceramic glass will only grow as we explore new boundaries in the field of technology and design. Innovation in ceramic glass manufacturing technology enables the industry to produce thinner, more durable components that can withstand more extreme conditions. Furthermore, sustainable production methods have become a priority to ensure that the production of ceramic glass produces a minimum ecological footprint.

Comparing ceramic glass with traditional glass further highlights its superior characteristics. Although both materials play an important role, ceramic glass performs excellent durability and performance under stress. This advantage consolidates its position in high pressure applications such as industrial machinery and professional scientific instruments.

Ceramic glass is not only a material; it proves the possibility of human creativity and engineering. Whether it’s enhancing the performance of a sharp-edge ring inductor or improving the aesthetics of a modern kitchen, ceramic glass can stay here, redefining the boundaries that may be possible.