Understand Ceramic Glass

Ceramic glass is a unique material that combines the best materials in ceramic and glass, resulting in a durable, attractive and versatile substance. Ceramic glass is known for its outstanding properties, separated in industries such as electronics, construction and household appliances. In the modern technical field, ceramic glass has high temperature resistance and thermal stability, making it highly sought after for specialized applications.

Ceramic glass properties contribute to its global appeal. The material exhibits extraordinary strength at high temperatures and is extremely resistant to thermal shock. Unlike traditional materials, ceramic glass can be designed to be transparent or opaque according to its intended application. Its sleek appearance and ability to withstand high pressure make it ideal for cutting-edge industries.

The characteristics that set ceramic glass apart

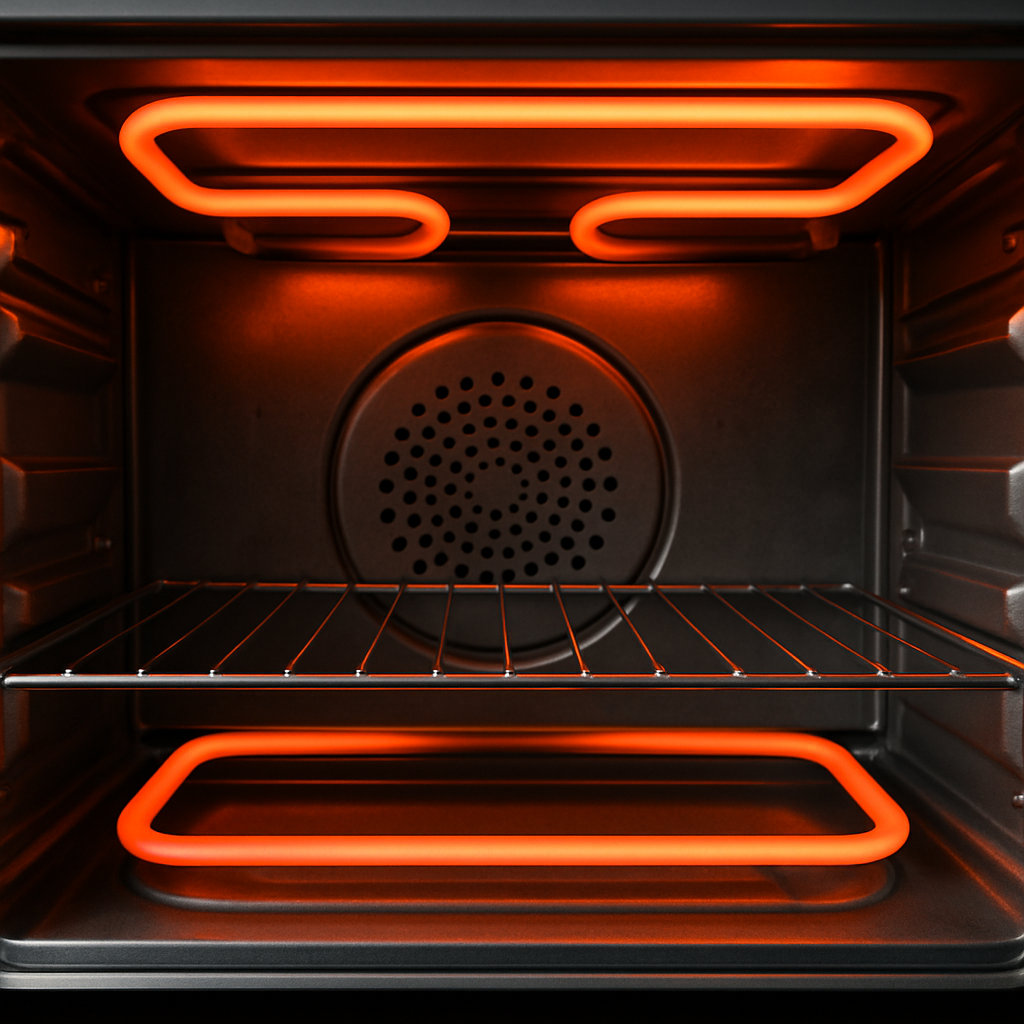

Thermal durability is often at the forefront when discussing ceramic glass properties. Although traditional glass is versatile, it cannot tolerate extreme temperature changes. Ceramic glass, on the other hand, can tolerate rapid thermal changes, making it essential in industries that require reliability. High temperature ceramic glass is often used in engineering, cooking surfaces and even aerospace applications.

Another reason for the popularity of ceramic glass is the minimum expansion under heat. This property ensures that it remains stable and crack-free, thereby improving its life and availability. In addition, ceramic glass has chemical resistance, making it suitable for environments exposed to corrosive substances or moisture for a long time. Compared to traditional glass products, ceramic glass is still elastic under conditions that usually degrade other materials.

Application of Ceramic Glass

The versatility of ceramic glass applications is found in various departments. In electronics, ceramic glass is valuable for insulating components and optimized energy transfer, just like the ** iron core ring inductor**, ensuring smooth voltage regulation and efficiency. Engineers often prefer ceramic glass due to their adaptability and high performance in demanding environments.

Ceramic glass manufacturing has been developed to include the latest technology, allowing the production of professional components that meet strict industry standards. In addition to electronics, everyday cooking equipment like stoves also utilizes materials to achieve heat resistance and aesthetic appeal. It is seamlessly integrated in design and functionality, making ceramic glass available for both home and industrial use.

For those who compare ceramic glass with traditional glass, the difference is obvious. Although glass is usually cheaper and lighter, ceramic glass offers excellent performance in challenging conditions. The unique combination of properties in ceramic glass makes it the preferred choice for tasks that require elasticity and accuracy.

Conclusion

Ceramic glass represents the pinnacle of innovation in materials science. Its impressive durability, resistance and adaptability characteristics can be applied between engineering, construction and consumer electronics. Coupled with advances in manufacturing technology, ceramic glass continues to redefine the possibilities of technology and design.

Whether it is a cutting-edge product of **Ferritic core ring inductors** or used in daily applications, ceramic glass proves the driving force for human creativity and progress. From high-temperature ceramic glass to its application in precise hardware, this material will undoubtedly play a crucial role in shaping the future of the industry and technology.